Our manufacture has more than 28 years of experience in the production of wood plastic composite (WCP). It has extensive experience in development and innovation, achieving after many years of research and laboratory testing a unique product in the market that exceeds the performance and expectations of its consumers. We are proud to add him to the great BennerUSA family.

What is Wood Plastic Composite?

Wood plastic composite is panel or lumber product made from recycled plastic and small wood particles or fibers. It is an innovative and environmentally friendly product that is increasing its demand in the North American market. Our product has a lack of affinity for water, allowing the formation of single-phase composite and resulting in a product with excellent dimensional stability along with less variability than solid wood, it is also known that is naturally decay resistance against fungi or insect attack.

The greatest advantage of WPC is its environmentally friendly approach of using waste wood and recycled plastic material. Wood composite plastics have low maintenance cost as compared to that of solid wood. One of the main reasons responsible for the fast growth of WPC is its low-life cycle cost.

Uses: The most widespread use of WPCs in North America is in outdoor deck floors, but it is also used for railings, fences, landscaping timbers, cladding and siding, park benches, molding and trim, prefab houses, window and door frames, and indoor furniture.

Our main products include WPC Decking, Co-extrusion WPC Decking, Wall Panels and boards, WPC Fencing, Garden Houses, Flowerpots, and other outdoor decorative products.

It is a product focused mainly on:

- Energy Conservation

- Environmental Protection

- Innovation

- Development

Main Benefits:

- Complete Certifications – have been successfully certified to ISO9001-2015, CE, REACH, RoHS, FSC, GRS Etc.

- High Quality product – use high-quality materials for production. Products look like natural wood, colorful, durable. Waterproof, anti-corrosion, anti-slip, no bending, no color fading. Easy to install and clean, maintenance free.

- Environmental Protection Concept – follows the concept of environmental protection, created with sustainable methods that reduce landfill and use waste timber and plastics to produce products.

Wood Plastic Composite vs Timber

Why choose wood plastic composite products?

Let us show you in a summary table to help explain the key difference between WPC and Timber.

|

Wood Plastic Composite |

Timber |

|

| Humid Stability |

More stable |

Will expand after water absorption |

|

Durability |

Long |

Short |

| Termite Resistance |

Yes |

No |

| UV Resistance |

High |

Low |

| Acid and alkali resistance |

High |

Low |

| Weather resistant |

Yes |

No |

| Painting |

No need |

Yes |

|

Cleaning |

Easy |

Middle |

| Maintenance Cost |

Low cost |

High cost |

Products

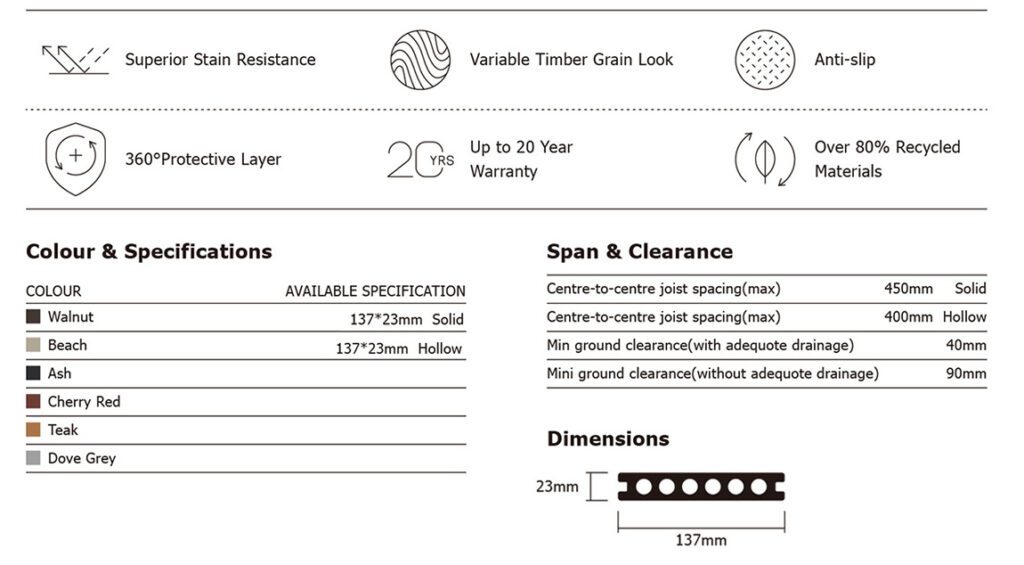

WPC CO-EXTRUSION SOLID DECKING

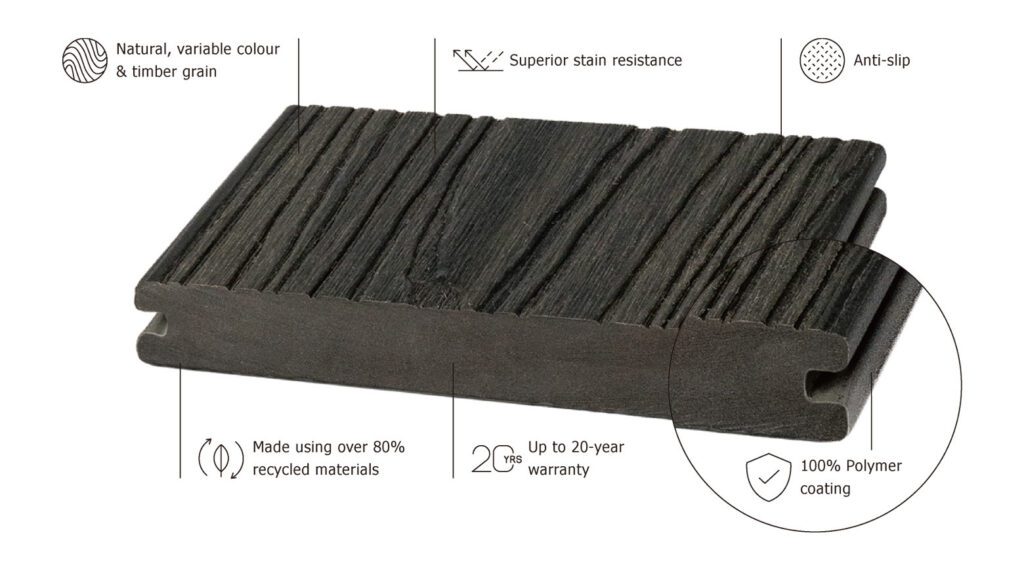

Co-extrusion composite decking is made from wood plastic composite core and engineering polymer covering. The covering is like a 360°shield to protect the core from water, UV, fungus, panting and scratching. By using the shield, WPC Decking can avoid problems like color fading, rot, crack, mold. Moreover, Co-extrusion Decking has the advantage of scratching-resistance, stain-resistance, more durable life and more color and wood grain pattern choice.

Detailed Introduction

Co-extrusion composite decking is made from wood plastic composite core and engineering polymer covering. The covering is like a 360°shield to prevent the core from water, UV, fungus, panting and scratching. By using the shield, WPC Decking can avoid problems like color fading, rot, crack, mold.

Moreover, Co-extrusion Decking has the advantage of scratching-resistance, stain-resistance, more durable life and more color and wood grain pattern choice.

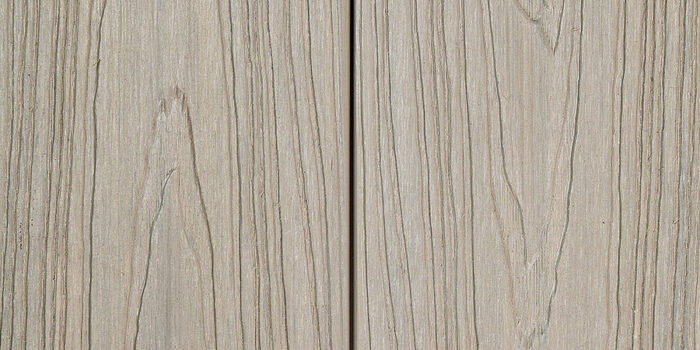

Walnut

Teak

Dove Grey

Cherry red

Beach

Ash

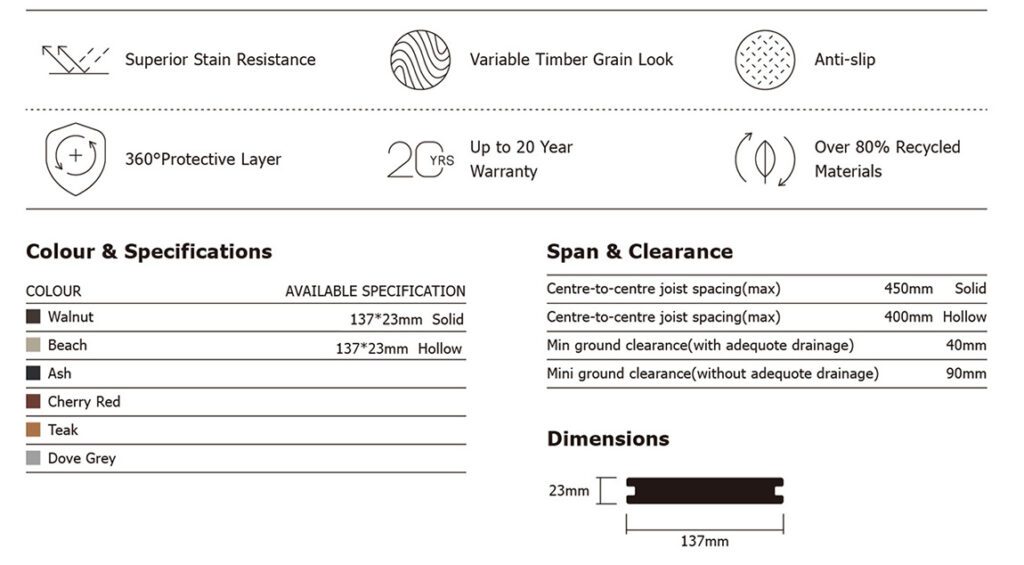

WPC CO-EXTRUSION HOLLOW DECKING

WPC Co-extrusion Decking uses the latest technology Co-extrusion. New material capped outside, the shell is made of a high performance and moisture-resistant polymer which is anti-scratches and easy to clean as well as keeps the inside WPC from water absorption. The shield and core are extruded simultaneously, so there are no adhesives or chemicals that are harmful to the environment. Natural surface and stable quality make the second-generation Co-extrusion Decking become more and more popular in the yard.

Detailed Introduction

Co-extrusion composite decking is made from wood plastic composite core and engineering polymer covering. The covering is like a 360°shield to prevent the core from water, UV, fungus, panting and scratching. By using the shield, WPC Decking can avoid problems like color fading, rot, crack, mold.

Moreover, Co-extrusion Decking has the advantage of scratching-resistance, stain-resistance, more durable life and more color and wood grain pattern choice.